Where and how a high-pressure tap is used

Shut-off valves for working with high pressure (VD) of various working media - liquids, including aggressive ones, gas, must guarantee reliable operation of industries. The leading place in this list is occupied by the fuel and energy complex. The main difference between such devices is the preservation of all the necessary performance qualities in the range of 10-80 MPa. Today we look at what constitutes a high-pressure cone and ball valve, as well as touch on other similar devices.

HP Stop Valve

Such valves include devices that are able to block media flows due to the reciprocating displacement of the locking element, which moves perpendicular to the surface of the housing along the center of the axis. It is a spindle, which is screwed into the thread of a nut fixed in place. Its location is in the lid or yoke (read also the article Ball valve DN15: device and installation features).

The running thread is submersible or external, it has self-braking, which allows the spindle to remain in an intermediate position, and the existing pressure of the working medium flow will not have any effect on the locking device. The design of the valve body can be:

| Direct flow | It is used in the case when it is impossible to reduce the flow at the outlet. |

| Mixing | Used to maintain a certain temperature by mixing two media. |

| Running gear | A fairly common option. It is installed on a straight section of the pipeline system. The main disadvantage is a zone of stagnant fluid. |

| Angular | Designed to connect the perpendicular elements of the pipeline. |

The junction of the rotating spindle and the cover can be of bellows or stuffing type. Conventionally - valves with diaphragm closure can also be considered valve.

Device characteristics

Disadvantages of shut-off valves:

- high level of resistance in the hydraulic plan;

- inability to use in viscous, extremely dirty liquid media;

- one way valve operation.

Thanks to the ongoing modernization of existing devices of this type, it was possible to significantly reduce the influence of negative factors on the quality of work, while increasing the advantages of devices:

- unchanged performance at high pressure drops;

- small stroke of the locking element to complete overlap;

- the instruction permits installation on the pipe in a convenient position for maintenance;

- small overall dimensions and weight.

High pressure cranes

Such valves are designed for operation in pipelines in which the pressure exceeds the standard. Therefore, the locking element in this case has an increased strength, with the most convenient method of overlapping, opening the flow of working media. Use 2 types of HP ball valves.

Conical

- A stopper serves as a locking element in this construction.

- The main advantage of the devices is the low price of parts and simplicity.

- This type of construction is not used for complete or partial overlapping of the flow of media in large diameter pipelines, as well as where pressure and aggressiveness are too high. Because of this, conical KVD is not so often used in the gas, metallurgical and oil industries.

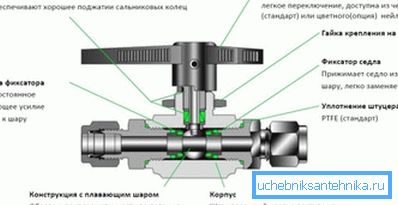

Ball

In this case, the locking element is a ball rotating around an axis. This design assumes high tightness, ease of operation, reliability and long service life of the device.

Because of these qualities, VD cranes of this type are used for a wide variety of pipe diameters. They can also be used for conditions when the temperature exceeds + 200 ° C, and for aggressive media.

The main consumers of products are:

- energy;

- chemical, oil, gas and metallurgical industries;

- utilities.

Tip: for pipes of small diameter, the device is installed by means of choke or coupling connection.

When it is necessary to shut off the flow in a large-diameter pipeline, the valves are connected by welding or through a flange. Open and close the locking element through the drive.

Requirements for HP Valves

The materials used for the manufacture of such products must comply with the working drawings. All parts must not have defects that may affect their density and reliability during operation. During production, the stages of stamping, forging, casting must be subjected to non-destructive testing using radiography, ultrasonic scanning, or an equivalent method.

The body of the nozzles and flanges must have a metric thread with a large pitch, a tolerance field of 6g, which corresponds to GOST 16093. The threaded hollows are rounded.

Tip: thoroughly grind all sealing surfaces.

Any type of defect that could affect the reliability and tightness of the seal should not be allowed.

It may be:

- sink;

- cleavage, fistula;

- crack, risks and sunsets.

It is prohibited to use in VD pipelines (over 35 MPa) for corrosive liquids and gas flanges with a smooth sealing surface and fittings of a cast type. The guaranteed service life of the VD armature elements must be 25 years or more.

Conclusion

Above were considered - shutoff valves VD, its features, as well as valves, which are used in this case. You also learned what requirements are imposed on a device of this type and what features they should have (see also the article Radiator valve — everything you need to know about this valve and control valve).

The video in this article will provide an opportunity to find additional information on the above topic.