Where and how is the needle valve used

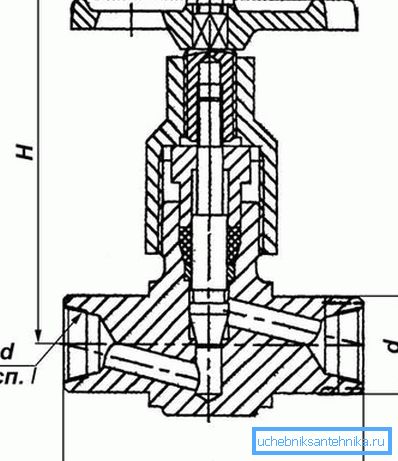

One of the elements of the control valve is a needle valve. With it, it is possible to control the flow of water and steam choking. Equipment is usually installed on the auxiliary pipeline, where the pressure does not exceed 9.8 MPa. The crane - the regulating locking device, is a kind of pipeline fittings. The movement of the locking elements occurs in parallel or reciprocating to the flow of the working medium.

General information

In the needle valve the spindle is the moving element. It is screwed into the thread of a fixed nut, placed in the yoke or on the cover.

Devices are available in various types, they are classified into:

- Shut-off, regulating and balancing - functional.

- Direct-flow, through passage and angular - special design.

- Needle and disc - over the locking element.

- Bellows and stuffing box - sealing cover with spindle.

- Remote and submersible threads - the location of the running nut.

.

Over 100 types of cranes are produced, which are divided according to their purpose:

- needle;

- regulating for pressure gauge;

- shut-off.

Their price depends on the material and size.

Use needle valve

- The device has a locking mechanism for the pressure gauge, install it on the pipeline in front of the pressure gauge, which allows you to turn it off when necessary and purge.

- It is also necessary in order to be able to automatically shut off the flow, if the very sensitive elements of the pressure gauge break.

Tip: Install the needle valve in the pipeline to connect, disconnect and purge the pressure gauge.

- Valve - control-stop valves, used in order to prevent the occurrence of water hammer in pipeline systems. They occur with very fast opening and closing of valves.

- The instruction recommends the use of devices in pipelines with long sections, which allows to avoid a sharp overlap of flow, which can lead to the destruction of the pipeline.

- The design of the device allows to withstand high pressure, reaching up to 220 atm and smoothly adjust the flow of liquid, steam or gas.

Tip: use a valve of this type in everyday life for equipment and pipelines that move gas, water and other liquids.

Characteristics and advantages

The equipment has several very important features:

- manual control;

- connection to the pipeline with a lens seal using a flange;

- coupling pressure gauge;

- closing the valve when the pressure gauge components are broken.

A needle valve is used to regulate with their own hands in a stepwise periodic flow of the working medium, including the heating medium in the heating system.

He has three positions:

- closed;

- partially open;

- fully open.

| Advantages of the device |

|

| disadvantages |

|

Choosing a needle valve

When determining equipment modifications, it is necessary to decide where it will be applied and for what.

The valves are made of different materials, including:

- become;

- cast iron;

- wrought iron;

- stainless steel;

- brass.

The valve, made of stainless steel, has anti-corrosion properties and is used as a regulating-locking device in an aggressive working environment. With its help it is possible to block the flow, ensuring the reliability and tightness of the valve due to the needle element. (See also the article The device of the mixer for the sink: features.)

When selecting a device, take into account also the area and industry in which it should be operated:

- oil;

- chemical;

- food;

- utilities;

- water supply and heat supply, in pipelines with various gases and liquids.

To determine the exact crane you need, consider for which medium it should be used and from which material it should be made. The latter are distinguished by their characteristics, corrosion resistance, operating temperature and price.

For example:

- Gray cast iron is suitable for not very important areas and water supply.

- Bronze - for a corrosive environment, it is resistant to rust.

- Carbon steel is durable and reliable, used in high pressure environments.

- Chrome-molybdenum steel is used at heating plants due to its high heat-resistant characteristics.

- Stainless steel and heat resistant nickel, with a high degree of corrosion resistance.

Tip: you can use needle valves of these materials at a pressure of 0.5-70 MPa.

Why use a needle valve

- In the systems of water supply and heating of long length for a smooth stop of the flow of fluid, which makes it possible to avoid dangerous and unpleasant moments.

- Devices may not be used when other valves and valves are already used in the piping system.

- Cranes are mounted on pipelines and have a long service life.

- Before selecting a device, we recommend determining the required diameter, as well as the material of manufacture.

Conclusion

The use of needle valves allows you to establish a stable operation of pipelines and other systems. Appeared reliable protection from many emergencies. The video in this article will provide an opportunity to find additional information on the above topic.