Where and how is used a ball valve 1-1-2

In the construction of household and industrial pipelines use a variety of materials - HDPE or low-pressure polyethylene, metal and plastic. And every year designers try to simplify the installation procedure, improve the reliability of pipelines and increase their service life. Not the last role is played by the ability to quickly and easily install various locking devices on them, among which there are specialized taps for a specific type of pipe. In fact, they will be discussed in this article.

Features of ball valves

Different models of cranes are used for pipelines, depending on:

- nature and purpose of the working environment;

- pipe diameter;

- pipeline design features;

- crane installation locations;

- method of installation.

How and where equipment is used

The pipes are mounted on the pipes at the junctions of different sections, as well as at the points of flow control. They allow not only to ensure tightness in this case, but give the opportunity to open and close the cross section to adjust the passage of the substance. The latter can be hot, cold or chemically aggressive.

Ball products are used in systems:

- glaze;

- water supply (drinking and technical);

- gas supply;

- sewers.

Device models differ in appearance and composition of the metal used. For example, many manufacturers of faucets paint products for cold water in blue, and in red - for hot.

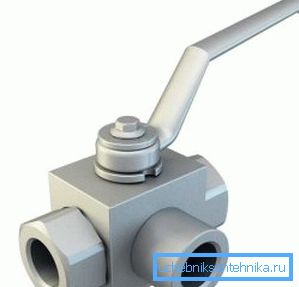

The design of the ball valve may be as follows:

- angular;

- checkpoint;

- multi-way (when there are 3 or more inlets).

Types of products

In addition to the method of installation, cranes are distinguished by the method of operation of their drive mechanism. Most often in the structures and systems for domestic purposes, where usually used pipelines of small diameter, used manual control device. In this case, changing the position of the handle is easier to do with your own hands.

Tip: this method is great for highways that are laid in accessible places. In this case, access to the ball valve must be equipped with additional protection in the form of fencing or locking mechanisms.

Apply today widely and cranes with gear. This mechanism makes it possible to increase the force, greatly facilitating the procedure for turning the valve. In addition, the compactness of the whole structure is ensured.

If the diameter of the pipeline is 150 mm and more, it is better to use automatic or mechanical types of drives.

You can manage them using:

- electricity (electrical);

- air (pneumatic);

- fluid (hydraulic).

Such designs allow you to control devices at some distance or to get full automation of flow control through pipelines. For example, this may occur subject to certain conditions, such as an increase or decrease in air temperature.

Installation

Consider below how you can connect the valve to a system of plastic pipes, which today are gaining more and more popularity among consumers, as well as from metal or metal-plastic.

There are several ways to do it yourself:

| Welding | The best tightness is ensured by using thermistor or butt welding. After using this connection method, the possibility of disassembling the unit and re-using the crane is excluded. |

| Flange | This option allows the installation and disassembly of the device without the use of special equipment. Traditionally, these cranes have only 2 “close” and “open” positions, therefore it is impossible to regulate the flow rate. They produce stainless steel or cast iron products, they are used on large-diameter pipes, for example, in the oil and gas industry. The devices have maximum strength, their cases are collapsible (2 parts) or cast. |

| Clutch | Such a connection is used in gas, heating and plumbing systems, where the pipe diameter is not more than 45 mm. Coupling taps for pipelines are the easiest to install and convenient to use. |

| Fitting | The nipple method involves connecting with nipples and nuts, and the connection areas are sealed with gaskets. This method makes it possible to repeatedly mount and dismantle the crane. |

Tip: You can also use the combined method when welding and flanges are used at the same time.

What to look for

- The main disadvantage of ball valves, which reduces the possibility of their use - a small size range. With increasing pipe diameter, the probability of selecting a device model for it decreases.

- The price of ball valves for plastic pipes is higher than other closure devices. At the same time, in terms of their service life, this cost is fully justified.

- When a device is needed to regulate the flow, if an incomplete overlap of the cross section occurs, it may become depressurized over time due to a change in the geometry of the stop ball. This happens due to exposure to the fluid passing through the pipeline.

- The instruction permits the use of spherical structures only in a system with low pressure. - no more than 10 atm for gas pipelines and 16 atm for water pipelines.

- Ball type devices create optimal conditions when using pipelines. With their help, it is possible to block them for repairs or when used in seasonal mode.

Conclusion

We have considered in this article ball valves. We learned how and where they are used, how they are installed, and also found out the shortcomings of this equipment. When you have to choose, you know what to look for. The video in this article will provide an opportunity to find additional information on the above topic.