Which pipes are better to use for wells in the garden

When ordering the manufacture of a well for water from a drilling company, the owner of a country house expects to receive a completely ready-to-use source of pure natural water that can last for decades.

However, it should be remembered that the qualitative composition of the produced water and the durability of an underground well largely depend on the material and quality of manufacture of the pipes that make up the casing. Therefore, when choosing a drilling company, it will be useful to know which well casing is best for use in each particular case.

Casing Material Selection

This article can not be regarded as a full instruction on the installation of casing, because it is quite a complicated process that requires the use of special equipment. It is almost impossible to do it yourself at home, so for drilling a well and installing a casing string, you need to seek help from professionals.

Here we will try to figure out which pipes are better for a well to use as a casing string, and also consider the main properties of pipes made from various materials.

What is casing for?

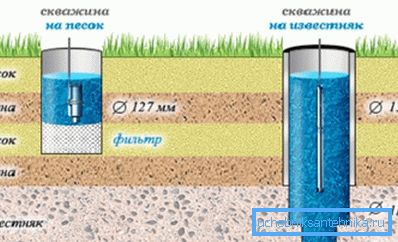

The casing pipes are lowered into the wellbore of a newly drilled well during its development, thereby protecting its walls from collapse, and the wellbore itself from falling into developed rock from adjacent layers of soil.

In addition, in the already finished bore, the casing pipes have a tight connection between them, which prevents poorly treated groundwater (the so-called supercharger) from entering the wellbore. Thus, only natural water of deep purification from an artesian aquifer gets into the water supply system.

The trunk of an underground well during its operation is subjected to significant loads and exposure to aggressive media, therefore the following requirements are imposed on materials for its production:

- High mechanical strength.

- Stability against ground pressure forces.

- High corrosion resistance in the aquatic environment.

On this basis, the following materials are most widely used, which can be used depending on the specific conditions and geological features of the soil in the drilling area:

- Steel (including stainless, galvanized, enameled).

- Asbotsement.

- Polymeric materials (PVC, HDPE, PP).

Tip! The inner diameter of the casing, regardless of the pipe material, must be at least 110 mm. This size is optimal for normal well flow rate, and in addition, it will be easier to choose a suitable model of a submersible pump in the future.

Ferrous metal pipe

The ferrous metal casing for many years has been deservedly in high demand when drilling wells for water. If it has a metal wall with a thickness of 6 mm or more, such a well is considered practically eternal, since its service life may be more than 50 years. This period is almost equal to the life of a high-quality well with a powerful aquifer.

In order to have a more complete picture, you should know some features of using steel as a material for the casing.

- Steel is an environmentally friendly material that, when in direct contact with water, does not release any chemical elements into it. Normal rust that forms on metal surfaces does not dissolve in water and, contrary to popular belief, does not increase the level of iron. To remove it, just run the water through a regular household filter.

- High mechanical strength and toughness of steel practically exclude breakage or destruction of the casing string during its installation.

- In case of clogging or silting of the well, as well as accidental ingress of foreign objects in it, it is allowed to perform drilling or other work using a drilling tool.

- A well with a similar casing can be installed even at a very deep level of the aquifer.

As for the negative qualities of this material, the main disadvantage is its rather high price. For this reason, it is necessary to think carefully over what period of operation the well installation is calculated.

The use of steel casing in most cases is justified for deep artesian wells, installed on the site of a permanent home for permanent residence. For the arrangement of shallow wells on the sand of seasonal use is better to use cheaper materials.

Tip! Better quality is seamless seamless pipe, as the weld along its entire length is its weakest point, in which cracks and ruptures can occur at high loads.

Stainless steel or coated pipe

As for the use of metal elements with additional protection against corrosion, sometimes a controversial question arises: which pipes are better for water wells, galvanized or stainless steel?

In fact, answering it, you can ask a counter-question: is it worth it to overpay a significant amount for stainless steel if a conventional black metal pipe has a service life equal to the period of operation of the highest production well.

Separately, it should be said about galvanized black metal. The fact is that with prolonged exposure to water on the zinc coating with time zinc oxide is formed, which is considered hazardous to human health. For this reason, galvanized elements can only be used for working with process water.

Steel pipes with enamel coating fully comply with sanitary and hygienic standards, however, they have one major drawback. The enamel coating has a low modulus of elasticity, so it is quite fragile. As a result, a large number of chips and microcracks are formed on the enameled surface during installation of the casing.

Water gets into them and the process of destruction begins, and penetrating corrosion occurs even faster, because the thickness of the metal for enameled pipes is used less than for ferrous metal.

Note! If the manager of the drilling company strongly recommends the use of any stainless materials that have a significant cost, it is more like a marketing ploy, in order to sell the more expensive product to the customer.

Asbestos cement pipe

Asbestos-cement pipes have been used for casing wells for many years and are an inexpensive alternative to steel products, but not all drilling companies, due to the nature of this material, know how to assemble them correctly.

Next will be described their main properties.

- Asbestos cement is an environmentally friendly chemically neutral natural material and does not release any harmful substances into the water during operation.

- The assertion that asbestos has carcinogenic properties is scientifically unfounded. In addition, the number of fibers that can get into the water is negligible, and given the peculiarities of their structure, they can be filtered by any household filter.

- Asbestos-cement products are very fragile, therefore, when installing them, special care must be taken. For the same reason, drilling operations in an already completed well are unacceptable.

- Due to the large wall thickness, the installation of asbestos-cement pipes requires a borehole of a larger diameter than for steel ones.

- They can not be used as a filtration column in wells on the sand, therefore, they are used only in artesian springs.

- Due to the physical characteristics of this material, their installation is allowed only in wells whose depth does not exceed 100 m.

Plastic pipe

Relatively new materials for the casing can be considered pipes from various polymers: PVC-U (non-plasticized polyvinyl chloride); HDPE (low pressure polyethylene) and PP (polypropylene).

Among the advantages of these materials are the following properties:

- Absolutely not subject to corrosion, even with prolonged contact with water.

- Do not collapse in the ground and do not contribute to the development of pathogens.

- Do not emit any harmful substances into the water.

- The main advantage of plastic products is their low cost and low weight.

Given the low strength of polymer products, the maximum depth of the well with their use should not exceed 60 meters.

Tip! As for the question, which pipe is better for a well, of plastic products, the nPVH polymer is the most optimal in terms of price and reliability.

Conclusion

After reading the material of this article, you can more confidently turn for help in installing the well to the specialists of the drilling company. A competent manager who sees that the client is at least a little versed in this matter will not openly offer him a product of inadequate quality.

More detailed information on the subject of interest can be obtained by watching the video in this article or by reading other materials in this section.