Why do we need a floor slab

Although the installation of the well is quite simple in technical terms, it is still a very time-consuming process, requiring large physical costs. In this regard, in order to extend its operational life, a floor slab on the well is used, although some for some reason simply call it a lid.

This applies both to the water supply facilities, and sewer and gas communications, where concrete rings are used to strengthen the mine shaft - this is what will be discussed below, and you can also watch the thematic video in this article.

About overlappings

Note. Concrete slab sewer manhole or any similar design is not for its complete blockage, and for the installation of a metal (concrete) hatch. As a rule, the dimensions of the slab of wells overlap are chosen under the ring, but sometimes such a plate can be square - then on the surface we see only a concrete pad with a hatch.

Dimensions

| product name | Dimensions in cm | Weight in kg | Approximate price in rubles | |

| D | H | |||

| PVK-8 | 100 | 15 | 200 | 1280 |

| PVK-10 | 120 | 15 | 280 | 1770 |

| P-10 | 120 | 15 | 280 | 940 |

| P-10 kV | 120 | 15 | 320 | 2400 |

| P-12 | 140 | 15 | 500 | 1560 |

| P-15 | 170 | 15 | 710 | 2250 |

| P-15 kV | 170 | 15 | 940 | 6800 |

| P-15 C | 170 | 15 | 710 | 2650 |

| P-20 | 220 | 15 | 1300 | 3870 |

| P-20 kV | 220 | 15 | 1800 | 13,100 |

| P-20 C | 220 | 15 | 1300 | 4250 |

| P-25 * | 275 | 15 | 2800 | 14100 |

*Note. The stove is oversized.

General rules

- As it was already noted earlier, it is desirable to select the dimensions of the slab of the well for a strictly by the size of the rings - in such cases not only aesthetics, but also production safety is guaranteed. In those cases when the mine is laid out with bricks, its cross section is obtained square, therefore such covers come in a quadrangular shape.

- Reinforced concrete overlapping of the well is installed on top of the last (upper) ring, but in cases where the brickwork has been made, it is installed on the finish line of this laying.

- To increase the strength, the instruction requires that a sand-cement mortar is applied between the slab and the ring (masonry) to fix. After installation, a metal hatch is installed in the hole, which consists of a support ring and a well cover, allowing the inlet to be raised above the ground, which prevents dirty water from flowing from the surface.

- When installing wells, truck cranes are used, since the mass of the rings and the floors themselves are large enough to be installed manually.

- The overlap itself, according to GOST 8020-90, is made of heavy concrete, where its class on compressive strength may not be lower than B22.5 (M300), and on waterproof W W A-I, A-III class reinforcement is used for the metal frame Bp-I. The brand of frost resistance (the number of freeze-thaw cycles) must be no lower than F-100, that is, no less than 100 of these same cycles.

- Depending on the diameter of the ring, the size of the plate is also chosen, and you see them on the table above; moreover, this size can correspond not only to the diameter, but also to the diagonal of the square. The hole for a metal or reinforced concrete hatch can be either in the middle or shifted closer to the edge.

- Such a construction practically (according to natural atmospheric conditions) is not afraid of temperature drops (even if they are quite sharp) dampness and moisture.. They are able to withstand large mechanical loads from vehicles passing through them, while maintaining their original condition and shape. Use in the manufacture of heavy concrete makes them very massive (sometimes around or more than 2 tons), which does not allow them to budge under pressure from the wheels of road vehicles.

Standard installation

Note. The metal (concrete) manhole cover should be mounted exclusively on the support ring. It is strictly prohibited to install it on the stove!

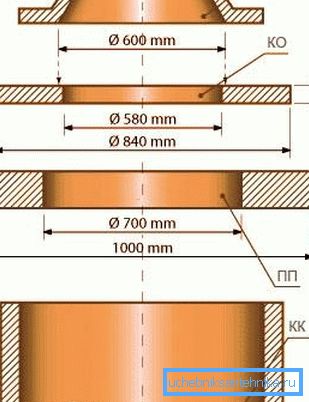

According to GOST 8020-90 3.900.1-14 release 1. Reinforced concrete products for round wells of water supply and sewage installation of hatches is made design with certain characteristics. These rules have been in effect since the days of the Soviet Union and their violation can lead to traffic accidents and even the loss of human lives.

The main purpose of the support ring (KO) is to protect the structure during the redistribution of the specific load. Due to KO, such a load weakens at least ten times, thus ensuring free passage of automobile and even tracked vehicles.

It is strictly prohibited to use self-made KO, but only certified, that is, manufactured in the factory. You can also not use brickwork or various cement casting devices instead.

Unfortunately, sometimes we have utilities, or rather their construction teams, neglect such norms, which leads to such consequences, as you see in the photo above.

Under the influence of moisture and the load from passing vehicles, the improvised KO begins to collapse, from which the well hatch sags below the road surface. This leads to the fact that the load is distributed unevenly and can burst not only the hatch, but the concrete slab itself.

Conclusion

Overlaps for wells, in the same way as hatches with supporting well rings, are an obligatory component of them during operation, and not only on the roads, but also at the entrances to houses, sidewalks and so on. This precaution is fully justified, since along with it the danger of getting there randomly is eliminated - just fall through without noticing the hole.