Why is there yellow water in the well: causes of the

One of the unpleasant situations that one has to face in arranging autonomous water supply systems is the case when the water from the well turns yellow. Moreover, the intensity of yellowing can be very different, ranging from a light shade, visible only "to the light", and ending with the appearance of a turbid suspension with an unpleasant smell.

There may be several reasons for such a phenomenon, and depending on them we will need to plan the strategy of our cleanup actions.

Causes of yellowing

Peatlands and clays

The water in the well of yellow color is a really unpleasant surprise. And if the minimum change in shade can still be endured, then over time the liquid begins to rapidly lose quality, and turbidity and deterioration of taste and smell are added to the color.

One of the common causes of this phenomenon is the close occurrence of the peat horizon:

- The peatland is a deposit of dead and mosses that have rotted away in anoxic conditions for a long time.

- As a rule, peatlands are formed on the site of swamps in fairly wet places. At the same time, there is a risk to stumble upon peat deposits in a fairly dry area, especially if land reclamation activities were carried out long ago in your area.

- A characteristic feature of soils with a high peat content is the presence of a large amount of organic matter, and first of all humic acids.

Note! Humic acids along with other organic compounds are the basis of humus - a complex of substances that ensure soil fertility. It is for this reason that wells prefer to dig on "poor" soils.

- When the aquifer is connected to the peat bog, the humus is actively washed out. The dissolved acids pass into the water, painting it in a characteristic yellowish color. The higher their content, the more intense the color.

Notwithstanding the foregoing, this reason is one of the most innocuous.

Much worse if the water turns yellow due to the high clay content:

- The appearance in the bottom layer of a large number of fine clay particles is evidence of the beginning of the silting process of the source.

- If the clay is abundant, then sooner or later the pump will begin to capture it, and the raised water will be muddy and yellowish.

Iron compounds

However, most often the answer to the question of why the water from the well turns yellow will be the high iron content.

This metal is contained in the soil in a variety of forms, and therefore the mechanism of its entry into the water will also be different:

- The simplest situation is the presence of insoluble iron in water. It usually gets into the water along with clay particles washed from the soil, and has the appearance of microscopic flakes.

- Much more difficult to fight with soluble iron. Upon contact with water, the minerals containing ferrous iron dissolve, so that the metal passes into the form of other compounds that cannot be seen. In this case, there is a staining of water in yellow color and a significant change in its taste.

- Another situation leading to yellowing is related to the vital activity of the so-called iron bacteria. These soil microorganisms live in an oxygen-free environment at great depth, and receive energy through chemical reactions between substances containing iron. The result of their activity is the transition of iron from the insoluble (trivalent) to the soluble (bivalent) form.

As a rule, in most cases, the ironing process is complex, which means that we will have to fight with bacteria, and with a high content of the substance entering and the soil.

Methods of struggle

Peat water purification

The fight against the yellowing of well water and the deterioration of its quality may well be waged with your own hands. Naturally, the amount of work to be done is considerable, but in any case, there is not much choice left.

If the cause of the yellow shade is peat, then this phenomenon should be dealt with as follows:

- First, it is necessary to completely eliminate filtering through the joints of the well rings.. To do this, we pump out water from the well, and then we coat all the cracks and cracks with a sealant based on liquid glass.

Tip! When building a new well, experts recommend waterproofing from two sides: from the inside, we seal the joints with sealant, and from the outside we cover all rings with a moisture-proof compound.

- Secondly, it is necessary to systematically clean the aquifer. At the same time, we remove silt, clay and sand from the bottom layer, which can cause turbidity of the liquid.

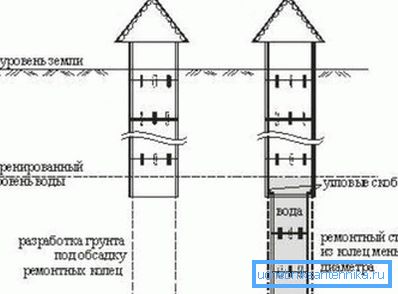

- Thirdly, if the peat horizon is close to the surface, you can simply deepen the well.. To do this, drain it and deepen the bottom of a few meters. This will allow cutting off the peatland with the help of concrete rings, and the filtration of humates into the water will stop almost completely.

- An alternative to this method is the drilling of a bottom well. Of course, the price of such a solution is high, but water, raised from a depth of 25-30 meters or more, will definitely be devoid of organic impurities.

- Finally, it is possible to partially reduce the content of humic acids by forming a gravel bed. To do this, lay a layer of gravel up to one and a half meters thick on the cleaned and deepened bottom. At least we will get rid of sand, clay and suspended silt particles, so the water will become much less yellow.

Iron removal technologies

The instructions for removing iron compounds from a well depend on the form in which it is presented there:

- With insoluble iron-bearing minerals, the easiest way is to remove them by simply passing water through a layer of gravel or sand. To this end, we build a powerful gravel filter for a well at the bottom of the structure, where most of the suspended particles settle.

- You can also install a mechanical filter at the pipe outlet from the well, securing it in front of the pump. Naturally, in this case, the filter must be periodically cleaned, and the barrier elements (cartridges, grids, etc.) must be replaced.

- The least expensive method is to settle the liquid. To do this, you need to set the capacity of a sufficiently large volume, and then relatively clean water will flow into the house. As is the case with the filter, the tank must be periodically cleaned, removing the bottom sediment.

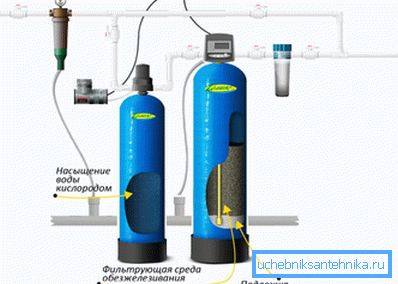

- As for soluble iron, systems with additional oxidation are usually used to remove it. As an oxidizing agent, potassium permanganate, which is relatively safe for humans, is widely used. At the same time, potassium permanganate artificially saturates with oxygen the adsorbing substance in the filter, and when passing through this filter, the iron turns into an insoluble form.

- However, to date, the availability of potassium permanganate is declining, and the reasons lie exclusively in the legal plane. That is why for the additional oxidation of iron, hydrogen peroxide, sodium hypochlorate, ozonation, etc. are used.

- The most cost-effective solution is cleaning with forced aeration: before it enters the filter, water enters the aeration chamber, where air is passed through it under pressure.

- In addition to the oxidation of iron and its precipitation, degassing is carried out - removal of hydrogen sulfide and other gases from water, which adversely affect its quality.

As a rule, such systems are mounted outside the well, either in a caisson or in the basement of a house. Their disadvantages are high energy intensity and significant cost of equipment.

In addition to cleaning the water itself to combat yellowing, you can try to reduce the bacteria content in the well. To this end, the walls and bottom of the dried container are treated with either a solution of bleach or potassium permanganate.

This event contributes to an increase in water sterility. However, it should be remembered that immediately after cleaning water should not be consumed: at least two weeks it must be boiled before to remove the active reagents.

Conclusion

If there is yellow water in the well - it is necessary to take measures. And it is desirable that they are complex: so we can provide the most high-quality cleaning and improve such characteristics as color and smell. Of course, the amount of work to be considerable, but in any case it is much cheaper than digging a well in a new place without any guarantees. The raised issue is discussed in more detail in the video in this article, so we recommend examining it before getting started.