Wiring water from the well: build the system

Perhaps today the typical water well pattern is known to everyone who has been at least a little interested in this topic. However, the procedure for equipping a water supply system based on such an installation has a number of nuances, and therefore it is worthwhile to study the technology in advance.

Then, when laying pipes and connecting equipment, there will be no questions, and problems will be solved promptly and with minimal costs.

Water source

Types of wells

Any scheme of water supply to the house from a well is built on the basis of a key component - the very source of water.

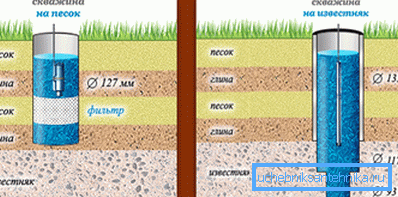

To date, all wells, depending on the characteristics of the substrate, are conventionally divided into three groups:

- Sandy - the most simple and cheap in the arrangement. The disadvantage is a relatively short lifespan (up to ten years), and rather fast silting. Suitable for installation in the country.

- Clay requires a little more responsibility when drilling a well, but otherwise they have the same advantages and disadvantages as sandy ones.. Should be used regularly, since after about a year without operation it will be very difficult and expensive to restore the silted well.

- Limestone (artesian) wells are considered to be the best.. The scheme of drilling a well in limestone water assumes a depth of 50 to 150 meters. This provides a margin of reliability and durability of the water source, and in addition - improves the quality of natural filtration.

Making the choice of the type of well, one should not pay attention to such a parameter as the price. The fact is that the arrangement of autonomous water supply is a task in itself very expensive, and it is better to invest in this project once (choosing high-quality equipment and inviting professional craftsmen) than to reap the dubious “fruits of savings” in the form of impressive repair bills and source recovery.

Pump selection

The next step in building a water supply system is the selection of pumping equipment.

Here the instruction recommends paying attention to the following points:

- As a rule, for small cottages models with high productivity are not required. Knowing that about 0.5-0.6 m3 of water is needed to operate a single tap over an hour, a pump is usually installed that can provide inflow of 2.5-3.5 m3/ h

- Also take into account the highest points of the selection of water. In some cases, to provide the necessary pressure on the upper floors requires the installation of an additional pump, because the downhole water-lifting device does not cope.

- Virtually all models of well pumps are characterized by a fairly high level of energy consumption. Taking into account this fact, it is worthwhile to take care of the power conditioner in advance. And if in your village electricity is often cut off, then the generator will not be superfluous.

Well equipment

The equipment process itself is usually carried out by the same company that conducted the drilling.

However, you should also study it - at least in order to ensure the quality control of the execution of working operations:

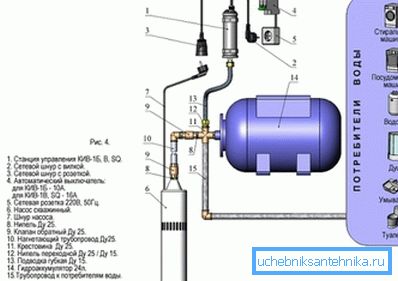

- The selected pump is lowered to the design depth and suspended on a cable or durable cord.

- Through the neck of the well with the installed head (a special sealing part) we draw a hose for supplying water and a cable that provides power to the pump.

- Some experts advise to attach the hose to the cable. This is quite convenient, but you need to remember that at the points of attachment the hose should not be clamped in any case!

- Also near the mouth mounted lifting device - manual or electric winch. You can do without it only at very small depths, because, the deeper, the more you will feel not only the weight of the pump itself, but also the weight of the hose with the power cable, and the weight of the cable.

Tip! The cap, valves and derived water pipes must be protected from external influences. Most often they are hidden in a small recess, lined with a brick inside and covered with a lid.

This is the type of layout of the well water device. However, this is not even half the battle: we need to build a whole system on this basis.

Water supply system

The main elements of the system

As we noted above, in addition to properly installed and properly operating water-lifting equipment, we will need many details to provide the house with water from a well.

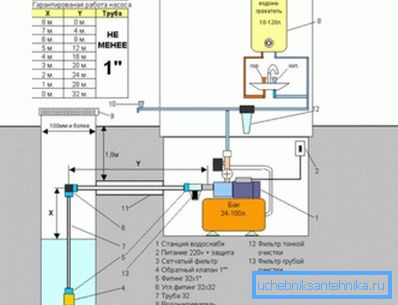

Among them:

- Supply pipe through which water from the well will flow to the house.

- Hydroaccumulator, which is a water tank that maintains a stable pressure inside the system.

- A relay that enables and disables a water-lifting pump, depending on the pressure level in the tank.

- Relay dry running (if water ceases to flow into the pump - the system is de-energized).

Note! Many models of borehole pumps are equipped with built-in fuses, eliminating dry running.

- Filter system for well to clean and optimize water parameters. As a rule, includes filters for coarse and fine cleaning.

- Pipelines and shut-off equipment for wiring around the premises.

Also, if necessary, the scheme of water supply from the well to the house includes a branch for the water heater. This makes it possible to provide hot water.

Pipeline laying

With certain skills, the system itself can be assembled by hand.

We do it like this:

- We are digging a trench to lay a pipe from the wellhead to the house. It is desirable that it takes place below the level of soil freezing.

- Lay the pipe (preferably polyethylene with a diameter of 30 mm). If necessary, we wrap the pipeline with insulating material.

- We get a pipe in the basement or underground space through special products. This part of the pipeline must be insulated!

System installation

Next, go to the construction of the accumulator:

- A hydroaccumulator (plastic container with a capacity of up to 500 l) is installed as high as possible - this will provide us with a natural pressure control. At the inlet, we install a pressure switch, which, when filling the tank, will shut off the water supply.

- In some cases this is not enough. Then we additionally install an automatic pumping station - a complex of several relays, pressure gauges and a membrane tank receiver.

- The receiver, equipped with a separate pump, provides a smooth change in pressure in the battery, which has a positive effect on the performance of all systems. Without this part, the well pump engine starts up with each firing of the crane, which naturally leads to its early wear.

Note! Another advantage of the receiver installation is the compensation of water hammer due to the difference of a few seconds between the operation of the pressure relay and the actual shutdown of the pump.

- After the system is assembled from the hydroaccumulator and the pumping station, we proceed to the installation of the pipe wiring. For it we use polyethylene pipes. When watering a cottage or a country house, a diameter of 20 mm is enough.

- Pipes are cut using special devices. To connect them, we use a soldering iron with a set of bushings. The use of this technology allows to achieve maximum tightness.

- Alternatively, steel or metal pipes can be used. They are characterized by greater mechanical strength, but it is more difficult to assemble them. Yes, and detachable connections are still inferior in terms of tightness to soldered seams.

Pipe wiring is supplied to the points of consumption and attached to the taps. For safety, we fix the pipes on the walls with clamps.

We should also take care of the drainage system. When designing it, it is important to place the cesspool or septic tank in such a way as to completely eliminate the filtration of effluents into aquifers. First of all it concerns sand wells, which are distinguished by shallow water.

Conclusion

The given scheme of water connection from the well has many variations, but for the novice master it is the one that is optimal. Of course, the simple procedure described cannot be called, and its laboriousness is quite large, but if necessary, you can understand all the nuances. Well, if there are still questions, we recommend that you study the video in this article.