Wooden wells: features, types and construction technology

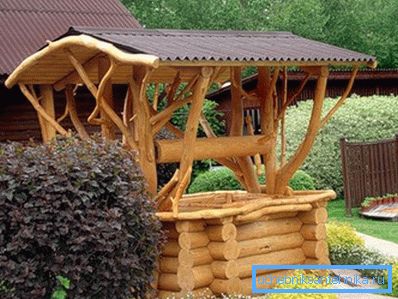

The wells of wood since ancient times were a symbol of Russian culture. To this day, they have not lost their relevance, but on the contrary - they became fashionable again, because with the help of this natural lumber, you can make both semi-antique wooden wells and more modern models that will harmoniously fit into almost any landscape design.

In a word, with the help of wood you can create a real work of art, which can be the main decoration of a country plot. In addition, a wooden well built on the site will give it a special cozy atmosphere, emphasizing its individuality and a certain style.

In addition to attractiveness, wooden wells have a lot of advantages. For example, since wood is an accessible and easy-to-use material that does not require a special tool, then anyone with construction experience will be able to make a similar structure with their own hands with the knowledge of technology..

And people also say that water from a wooden well has healing properties, so, probably, the tradition to build sources for the extraction of drinking water from this material began to revive again.

Types of wooden wells according to the method of construction and purpose

There are wells as completely made of wood, and only lined with this material. The first option can be attributed mine structures. (See also the article How to make water from a well.)

It is such constructions that are considered to be true traditional Russian sources that our ancestors built. However, when choosing this type, it should be noted that the final price of such a well will be very expensive, its production is more laborious and the whole process of its creation will take a lot of time.

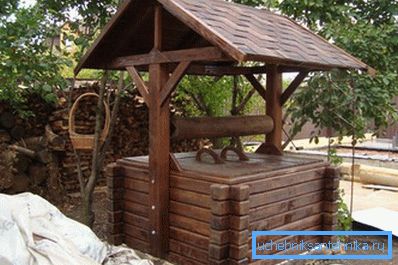

Tubular structures are the modern analogue of the mine variant. In this case, logs can only be used for decorative purposes, since a wooden blockhouse for a well of concrete rings is built only around a ready-made source solely for decorating or creating an imitation of a real old building.

There is also just such a type as a decorative wooden well, which, moreover, how to decorate the dacha plot, no longer has any operational function. In a word, similar log houses are used only to give the landscape a certain style, but there is no water in them. (See also the article How to draw water from a well to a house with your own hands)

Note! For decorative designs usually use a rounded log or profiled beam, as these treated materials look neater and more beautiful.

Choice of lumber, device mine design and technology of its construction

What wood can be used for the construction of the mine source

The first quality that wood for a well should possess is a high indicator of its moisture resistance. Also, when choosing rocks, it is also taken into account that the tree should not affect the taste properties of water. For these reasons, not every wood is suitable for the manufacture of wells.

Note! First of all, the wood for the well must be dry, not shed by a worm and insects.

So, for the construction of mine structures, you can use the following rocks, each of which has its own individual characteristics:

- Oak. It is the most durable and resistant material, which, being in a wet well environment, retains its positive qualities for many decades. In some Russian villages to this day you can see the wells built in the last century. In order for the underwater part of the well to serve even longer, it is often made of bog oak. Such wood is made for a long time, so it is considered an expensive pleasure. To make a bog oak, the blanks are first dried for at least six months, then a log house is assembled, all parts are numbered with waterproof paint, and then the structure is completely dismantled and logs are placed with running water for several years.

- Larch. This breed is successfully used for the manufacture of both underwater and surface parts of this source. It is a durable, non-rotting material. However, the price of larch is also not considered cheap.

- Hornbeam. Such wood in its qualities very much like oak.

- Birch tree. This breed has a low cost, but it should be noted that such wood is short-lived.

- Spruce. This lumber is rarely used for the manufacture of wells, as it is characterized by strong drying, it gives cracks and is well prone to rotting.

Also for the construction of wells used elm, aspen, willow, alder, linden, pine. It should be noted that the last two rocks can be used only for the part that is located above the water. (See also the article Well or Well - what to choose.)

Note! Since aspen is capable of giving the water an unpleasant bitter taste, it is chosen only in exceptional cases. In addition, it quickly decays, so that the water will get a putrid odor.

What is the source of the mine

If the question arose of how to make a wooden well with your own hands, then before you start doing this, you first need to study the device of the mine source.

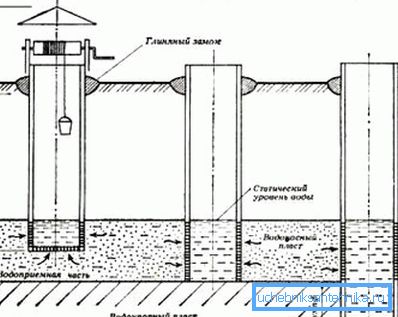

The design of this type includes such elements as:

- tip;

- water receiving part;

- the trunk, which is a section extending from the lower end of the tip to the beginning of the static water level.

Mining buildings are divided into subtypes such as:

- perfect with a sump (grenade launcher);

- imperfect (incomplete);

- perfect (complete).

In the latter type, the influx of water is carried out exclusively through the walls. The fastening of this design reaches the impermeable formation, in which it rests. The crib in the perfect type of source performs the function of an additional tank.

He is satisfied in the case when the aquifer does not exceed a height of 3-4 m. When its height is greater than this indicator, the water supply in this structure can be increased with a tent, which is made by expanding that part of the structure, which is located under water .

In the imperfect type of structure, the mount is not enough to the underlying layer, which lies below the aquifer. The tide of water in this case can be carried out both through the walls and the bottom.

The intake part in the imperfect construction should be made with a bottom filter, which should consist of 3 layers of gravel with different grain sizes. At the same time, the granularity in each upper layer should be 7 times larger than in the lower one.

What is the principle of constructing a log house for a mine-type well?

The optimal shape for a wooden well is a square. Most often, such structures are erected in the size of 1 by 1 m.

The frame is made of treated cut or whole logs. When the last option is chosen for this, when assembling the structure it is much easier to achieve a tight fit, which will improve the tightness of the walls of the well.

Note! The best time to dig a mine is from June to September. At this point, the level of the occurrence of water has the greatest depth.

The process of assembling a log house for such a design should begin even before digging a mine. It should be noted that this should be done on the surface of the site, marking each crown of the structure. This will facilitate the subsequent assembly of other elements.

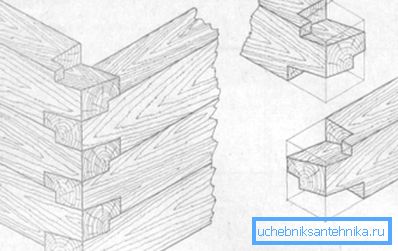

Logs must be mated directly in the corners of the log house. In this case, it is better to choose a method in the paw with a radical thorn without residue (darkness). This type of joint will allow a good compaction of the angle.

The crowns should be combined with the dowels, the height of which should be approximately 9-10 cm. Vertically they should be installed in the range. This will eliminate the separation of the lower elements from the top.

Neighboring crowns must be fixed with steel brackets. In addition, in the corners they need to connect with the help of bars, and on each side in the middle - to fix the boards.

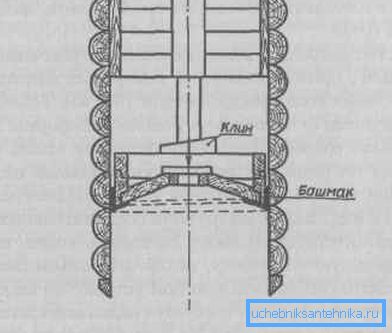

In order to make it easier to lower the log house into the mine, its base should be expanded, providing the lower part with a cutting knife called a “shoe”. It is easy to make it yourself with a steel corner. Especially this adaptation helps in cases where the depth of the source reaches 20 meters or more.

There is another method of manufacturing this well, in which the assembly of the log house occurs directly in the mine itself from the bottom. This option can be used with a source depth of not more than 7 m, when its walls do not collapse and the tide of water is not so strong.

In this case, first dig the mine to the desired depth. In this case, it is necessary to organize a temporary strengthening of the walls. Further, a frame is installed at the bottom of the excavated pit, which will serve as the basis, on which the entire structure will be assembled using the method described above. Sometimes for these purposes they use logs (logs) sawn along.

Conclusion

Finally, it should be noted that, like other structures, wooden wells require periodic repairs. Evidence that it is time to repair the wooden well with your own hands will be a degraded water quality.

Watch the video in this article, and you will learn more about these traditionally Russian constructions, which came to us from a distant history, and still remain in some cases the indispensable attributes of a country site.